5 Thoughts on LEGO's (Ace) Manufacturing

PLUS: Apple Watch at 10, McKinsey AI bot.

Thanks for subscribing to SatPost.

Today, we’ll rip through some fun facts about LEGO’s manufacturing prowess.

Also this week:

McKinsey Created an AI Chatbot

Apple Watch at 10

…them wild posts (including a great Daniel-Day Lewis film idea)

I dropped a deep dive on LEGO for my Caffeinated Deep Dive podcast a few months ago.

If you haven’t listened yet, my dopamine receptors will be forever grateful once you do and I check the stats on the Acast podcast hosting service later today (Apple, Spotify, YouTube).

One major theme I tried to convey in the episode is that LEGO has some incredible engineering and manufacturing chops. Most people intuit this when they step on a stray brick in their kid’s room and spend the next 8 minutes in agonizing pain because these things are seemingly indestructible.

But it is even more impressive when going through the full LEGO brick development process.

The Danish toymaker currently produces more than 25 billion new bricks a year. Crucially, every single one of them has to fit with the existing stock of ~1 trillion bricks produced over the past 60 years (off the top of my dome, the only other institution that has manufactured something with as many zeroes is the Fed Reserve printing the US Dollar).

This manufacturing consistency is why the bricks you used to chew on when you were growing up will work with the new Minion set you bought your nephew for Christmas. Seriously though, knowing that every LEGO brick will work with every other LEGO brick ever created is a major part of how LEGO maintains mindshare. It’s a physical social network that friends and families can pass old and new sets around knowing that everyone understands how they work and that they will work.

Over the past 20 years, sales have 10x from $1B to $10B. LEGO is a private company but if we put a conservative 5x multiple on sales, it's is worth at least $50B. It's already the largest toymaker in the world and largest education company if you want to toss it in that bucket (side note: Denmark's population is ~6m and they've given us LEGO, Ozempic and the word “Bluetooh”...I repeat: LEGO, OZEMPIC AND THE WORD “BLUETOOH”!!!! LEGENDARY!!!!).

On that note, here are 5 things I found fascinating about LEGO brickmaking:

The LEGO Patent and “Clutch Power”

Manufacturing Precision

Running Factories 24/7

LEGO’s Internal Brick Currency: “Frames”

Loose Ends

1. The LEGO Patent and “Clutch Power”

When LEGO was founded in the early-1930s, the Danish company was making wooden toys. The transition to plastic took place in the late-1940s. The LEGO brick we now know was launched due to a confluence of social, educational and technological changes as detailed in "The LEGO Story: How a Little Toy Sparked the World's Imagination”, written by Jens Andersen.

On the social front, Europe was re-building after World War II. Meanwhile, there was a growing recognition among academics that children could learn through play (LEGO is a riff on the Danish phrase"Leg godt", which translates to “play well”). On the technology front, there was the plastics revolution, which was catalyzed by material science breakthroughs during the war.

Throw all these developments into a pot, mix them up and you get plastic toy bricks.

LEGO wasn’t actually the first, though.

A British toymaker named Kiddicraft had pioneered interlocking toy bricks in the 1930s but was a fairly small-scale operation and didn’t leverage the post-War plastics innovations. Inspired by Kiddicraft, LEGO started selling plastic bricks in 1949 and they were called Automatic Binding Bricks.

But there was a catch: the first LEGO bricks were hollow. Customers complained that a gust of wind could knock over a tower or building structure.

Fast-forward to 1958. Godtfred Kirk Christiansen — son of LEGO founder Ole Kirk Christiansen — had one of the most baller “ah hah” moments in the history of capitalism and realized how to make plastic bricks stay together.

He developed the famous LEGO interlocking structure with tubes inside the brick and studs on top of the brick. It only took 5 days from idea to design.

In 1961, the official US patent was issued for a “toy building block” which has “eight primary protuberances and three secondary protuberances”. For those wondering, the dictionary entry for “protuberance” is exactly what it sounds like and also kind of hilarious: “a thing that protrudes from something else”.

This new invention created what is known as “clutch power”.

Also clutch: the fact that six of these 8-stud LEGO bricks can turn into 900,000,000 different combos (aka LEGO’s system of play). LEGO added to the party with Duplo in 1967, Minifigs in 1978 and Technic in 1982.

***

2. Manufacturing Precision

To ensure every brick can create “clutch power” — and is able to fit with the ~1 trillion other bricks ever made — LEGO is well known for its manufacturing precision and being a constant threat to your bare feet.

A tiny mistake in any single LEGO brick is multiplied across however many bricks are used. So, the bricks have to have a high fault tolerance. It’s widely believed that the variability between different LEGO bricks is at most 0.01mm to 0.05mm (equal to 10 to 50 microns), which is less than the width of human hair.

During the ramp-up phase before the CyberTruck’s release, Elon even directly called out LEGO’s manufacturing process as a benchmark:

Due to the nature of Cybertruck, which is made of bright metal with mostly straight edges, any dimensional variation shows up like a sore thumb. All parts for this vehicle, whether internal or from suppliers, need to be designed and built to sub 10 micron accuracy. That means all part dimensions need to be to the third decimal place in millimeters and tolerances need be specified in single digit microns. If LEGO and soda cans, which are very low cost, can do this, so can we. Precision predicates perfectionism.

LEGO fans love nerding out on the product.

So, the internet is full of discussion boards on LEGO’s engineering. This thread from r/AskEngineers has solid takes and tries to tease out whether LEGO’s famed fault tolerance is marketing or legit:

“Getting those tolerances on relatively inexpensive mass produced blocks is pretty impressive. The fact that very few bad blocks seem to make it into the world is a testament to good processes.”

“Typical commercial injection molded parts in similar size range as LEGO's is in the range of +/- 0.1 mm to +/- 0.05 mm for typical tolerance and +/- 0.05 mm to +/- 0.03 mm for high precision tolerance. So the alleged Lego tolerance is pretty tight. I don't really know about their cost vs. tolerance trade off, but small tolerance is definitely useful when parts are meant to repeatedly stacked together.”

“From childhood experiences, LEGOs tolerances matter a lot when building anything of scale. The tiny imperfections in competing bricks tend to scale up into large flex, bowed, and wiggle in your entire structure. You end up with weird tensions and compressions that cause failures or misalignments all over.

If you look at world record builders, they always used the LEGO bricks because of exactly this. Either that, or money from LEGO and good marketing. But I’d bet it’s the superior products.”

“Depending on the piece, tolerances are typically in the range of around 10um, or 0.01mm. This means expensive molds, but very consistent product. Out of every million bricks they produce there are typically 18 ‘Out of Tolerance’ bricks. Or about 0.00002%. It’s fair to mention though that there are many tolerances considered when designing a part, and some are more important than others. For instance, the tightest tolerance is applied to the global dimensions of the bricks, but a more lax tolerance considered for the stud height, diameter, and true position. This works because when you are putting two bricks together it is happening at an interface we call a snap fit (or interference fit).”

“You could set out and make LEGO-equivalent bricks pretty easily. Making them at scale, at comparable quality, and comparable cost would be really hard... which is why every kid knows the competition blocks suck.”

On the last point, there’s an entire movement of “Alt Bricks” claiming similar quality and unique sets. In another Reddit thread, skeptical LEGO customers note how recent sets have pieces that are off-color, misshaped and leave gaps between bricks.

I don’t doubt that individual sets of Alt Bricks can stack up to LEGO. For some purists, LEGO may be making unacceptable trade offs between output, price and quality.

But the key difference is volume.

As we’ll discuss in the next section, any other alternative would face challenges trying to create as much product as a LEGO factory.

***

3. Running Factories 24/7

LEGO currently has six factories around the world.

The original is in Billund, Denmark and the toymaker has added sites in Czechia, Hungary, Mexico, Vietnam and China. In 2023, it started construction on a $1B factory in Virginia (which is especially important with the new global tariff regime…which may be over tomorrow…or back on…or back off…or back on…or back off).

It is not unusual for these factories to operate 24/7 cranking out bricks.

The LEGO YouTube channel has a very worthwhile watch on the process, which goes through the following steps:

A truck rolls up to the plant filled with 28 tonnes of plastic granulates.

The granulate is made of Acrylonitrile Butadiene Styrene (ABS), which is high-quality plastic according to the internet because I’m not a chemist and have never heard of those words or that acronym in my life before researching LEGO.

Granulates are sucked into silos and then piped into the molding area with aisles of high-tech injection molding machines (see image below).

The Granulate is mixed with dye (50 different colors) then piped to the machines and heated up to 320°C.

The mixture has the consistency of toothpaste and is pressed at very high pressure into the mold…and, voila, LEGO.

Running at full capacity, a LEGO factory — like a Fed Chair making the printer go brrrrrrrrrr — can churn out 5 million pieces an hour or over 100 million pieces a day.

The star of the LEGO manufacturing show is the mold. Each machine can only do one design at a time. To ensure the most tippity-toppity performance, each mold is frequently cleaned and the outputs are inspected for tippity-toppity-ness.

Check out this mold retired after producing 120 million bricks. Legendary.

Then, the finished bricks are scooped up in an elaborate automated system that moves boxes of LEGO bricks around the factory and into a storage areas. The final step is packaging. All of the required pieces are fed into plastic bags and LEGO employees ensure each box has the right bags and instructions.

An efficient operation will make 50,000 boxes a day.

It’s undoubtedly an impressive operation but let’s address a question raised in the previous section, “Is LEGO’s quality slipping?”.

I think it’s very plausible and has to do with a key performance indicator (KPI) for LEGO: according to a Harvard Business case study, LEGO factories optimize “throughput per square meter of factory floor space” and “the most straightforward way to increase productivity [is] to increase the number of inserts per mold.”

However, the problem with increasing inserts per mold is that the molds become larger and it’s more difficult to “ensure uniform molding temperatures and cooling across the increased number of cavities.”

Over the past 20 years, LEGO’s revenue has basically 10x from $1B to $10B. That’s a lot more volume and a lot more surface area for mistakes. What happens as LEGO goes to $20B a year in sales? Can LEGO maintain quality across all its factories in Europe, Asia and North America?

***

4. LEGO’s Internal Brick Currency: “Frames”

One way that LEGO tries to maintain brick quality is by reducing complexity in the manufacturing process.

In the early-2000s, the toymaker was near bankruptcy and a major reason was that it had expanded into too many product lines. At the time, LEGO manufactured ~12,000 different pieces. Part of the company’s successful turnaround was to simplify to ~7,000 unique pieces.

To keep a manageable portfolio of pieces, LEGO has since implemented an internal system called “Frames”. Jordan David Scott — the creative lead in the Lego Ideas program — explained it to The Verge:

Lego’s picker system requires each printed piece to have its own unique storage bin, so rather than continually opening more warehouses, Lego limits how many custom parts designers can introduce each year.

“We can’t make everything decorated. We can’t change every brick into every color,” says Scott. “Otherwise the portfolio would just explode in complexity, so we have teams that manage the complexity level.”

And those teams came up with one simple idea to stem the tide of complexity: “frames.”

Want a part in a different color? That costs designers a frame. A new piece? Spend some frames. Bring back an old out-of-print piece? That’s a frame, too. Every year, design leads like Scott are given a limited number of frames that they can spend on their entire portfolio for physical pieces that aren’t readily at hand. “If I have five products or 10 products coming out, I need to allocate where those frames go,” says Scott.

Doing so is “a bit of a puzzle” to figure out which sets will need lots of frames — the new Animal Crossing sets with their custom minifigures probably ate a few — and which ones can be built mostly out of preexisting parts.

Designers also try to save frames by sharing brand-new bricks with other teams, giving them a heads-up that they might come in handy for other sets, too. Some of that happens automatically: “When someone puts in an order for a particular color change, we can see it showing up in the library of digital bricks,” says Scott.

Some of it is designers intentionally pooling their resources: “If Ninjago are making something we could use, we kind of have a dialogue and say, ‘Oh, we can use this as well, that would be great, so maybe we need to get you a frame or something to share it.’”

Designers always want more frames for their sets, May says. But he explains those constraints are just part of the process. When designers don’t have as many frames as they’d like, they have to get creative — just like any other Lego fan.

That’s damn smart. As the saying goes, “constraints breed creativity”.

Knowing me, I’d probably get suckered into swapping my annual allotment of “Frames” for a month’s supply of Fruit By The Foot or Apple Sauce Cups from another designer’s lunch. And that’s why I don’t work at LEGO.

***

5. Loose Ends

So, yeah, go listen to the Caffeinated Deep Dives episode on LEGO (Apple, Spotify, YouTube) and pump my dopamine.

Let me wrap up with a bunch of random bullet points:

Sergey Brin and Larry Page encased their first tiny Google server in LEGO.

An entire Bugatti car was built out of LEGO Technic pieces and was actually drive-able.

LEGO used to make the coolest business cards…Minifigs that resemble the employee with their name on the front of the shirt and contact details on the back.

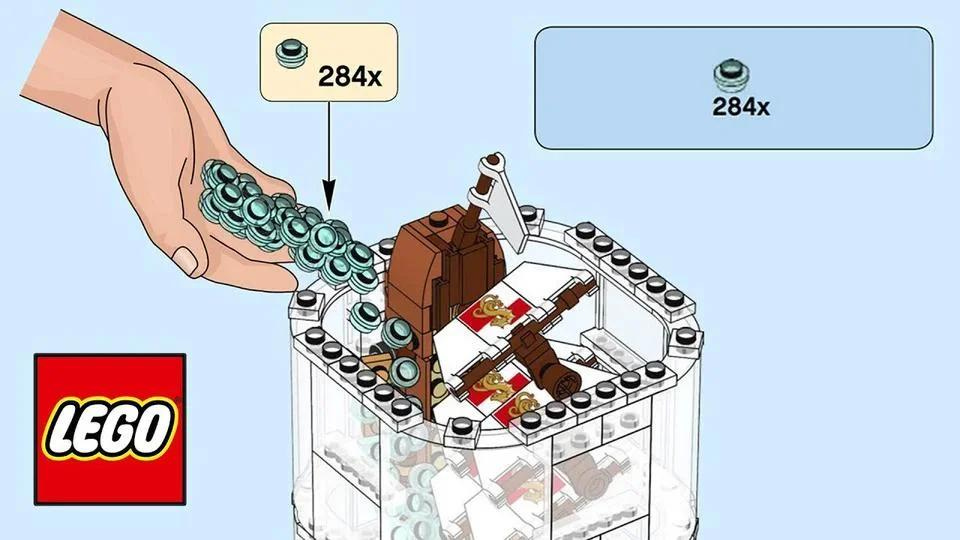

LEGO piece counts are very very specific…I’ve never not had enough pieces. One great example is this pirate ship set which asks for 284x of these small clear thingies but the set comes with 288x pieces (that number is divisible by 4, 8 and 16…which are the typical number of mold cavities)

PS. I really really enjoy AI-generating fake LEGO sets. It’s a problem. Dunno what to do about it. But yeah, enjoy these.

McKinsey Built Its Own AI chatbot

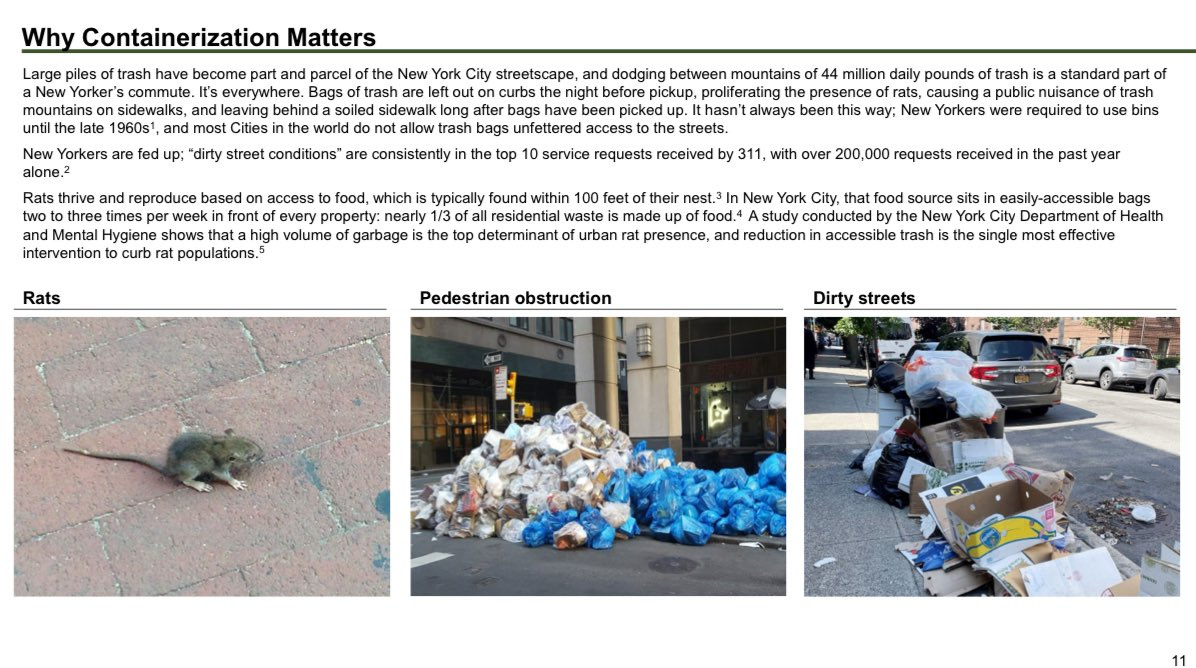

Last summer, it was revealed that New York City paid $4m to McKinsey to conduct a feasibility study on whether trash bins are better than leaving garbage on the street [insert laughter].

Since my brain has been completely warped by social media engagement dopamine, the very first thing I thought was: “Well, this is public money, so the feasibility study must be publicly available and I’m going to find it and try to make it go viral.”

I hunted down the PDF and pulled some incredible slides from a 95-page document titled “The Future of Trash” [Insert more laughter]. Sure enough, I put my findings on X and it got over 5 million views (including comments from various politicians).

McKinsey rebranded “garbage bins” as “containerization” and then described it as the “storage of waste in sealed, rodent-proof receptacles rather than in plastic bags placed directly on the curb.”

Then, they explained “why containerization matters”. Because New York City people have to deal with “44 million daily pounds of trash” that attract rats, obstruct pedestrians and dirty the streets.

Here’s my TLDR for the $4m feasibility study: YES! THE ANSWER IS YES! YES IT IS BETTER TO PUT GARBAGE IN GARBAGE BINS THEN LETTING RATS EAT ON THE STREETS!

I actually learned ton reading the document:

The two main types of containerization: 1) individual bins for low density locales; 2) shared containers for high-density.

Containerization has only become the norm worldwide in major cities in the past 15 years.

New York City first considered containerization in the 1970s but never conducted a feasibility study until now (clearly, McKinsey’s sales team has been dropping the ball)

There are numerous considerations for whether a city can actually deploy containerization properly:

Population Density: NYC has 30k residents per square mile (more dense than comparable big cities).

The Built Environment: Few places to “hide” containers due to history of infrastructure development.

Weather: Snow creates challenges for “mechanized collection” in the winter.

Curb Space: Mostly taken up by bus stops, bike lanes, outdoor dining and fire hydrants.

Collection frequency: NYC needs to double frequency of pick-up for estimated speed of trash that bins would accumulate.

Fleet: A new garbage truck will need to be designed to collect rolling bins at scale.

McKinsey’s proposed solution (literally garbage bins and shared containers) covered 89% of NYC streets and 77% of residential tonnage. There were three case studies of other major cities (Amsterdam, Paris and Barcelona) to further make the case.

The jokes obviously wrote themselves: “Wow, a 21-year old undergrad just billed $10k an hour to tell New York City that it needs to put garbage in garbage bins” (McKinsey’s rate for a newly grad on previous government contracts has been ~$56k a week or ~$3m on an annualized basis).

Look, I get how McKinsey is able to charge its seemingly insane rates. The buyer — whether government or corporation — either paying for “cover your ass” (CYA) insurance or has already decided what it wants to do but needs a third “objective” party to make the case so it can be shoved down the throats of the rest of the organization. The actual slide deck is <5% of the total value.

There’s also value in proprietary corporate best practices (McKinsey regularly consults with everyone in an industry) and creating a document to make sure everyone has the same context and gets on the same page.

Paying $4m to a newly grad to give you a 95-page PDF and be told “garbage should be in garbage bins” is obviously idiotic. It’s admittedly a lot less idiotic when the other factors are considered.

That takes us to a new recent story from Business Insider breaking down how all the major consultancies (McKinsey, BCG, Bain, Deloitte etc) are going balls deep on generative AI tools:

McKinsey launched its own AI chatbot: It’s called Lilli and “synthesizes the firm's entire body of intellectual property, which spans 100 years and over 100,000 documents and interviews”. Apparently, 70% of the McKinsey’s 45,000 employees use Lilli and do so an average of 17x a week. They built it internally and employees are not allowed to use ChatGPT due to sensitive inputs. On one anonymous message board, a McKinsey employee says its “‘functional enough’ and best for ‘very low stakes issues’" (hopefully, McKinsey didn’t train Lilli on Chinese corporate retreats, Purdue Pharma go-to-market and South African utilities).

BCG built a slide deck maker: It’s called Deckster and is “trained on 800 to 900 slide templates” and the most “popular features is a ‘review this’ button, which helps junior consultants by grading slides based on best practices used by midlevel managers and leaders. Anonymous internal reviews of Deckster actually say its very very good and some junior analysts are concerned it could take their work. BCG has a special version of ChatGPT for its 33,000 employees (and 18,000 custom GPTs have been created for internal use).

Deloitte has invested billions in AI: The consultancy blocks ChatGPT from its internal system to make sure employees don’t slip up with client data. Deloitte built its own alternative chatbot called Sidekick and recently “unveiled Zora AI, a new fleet of AI agents…[which is] trained in specific subjects — like finance or marketing — and designed to think like humans.”

Naturally, the McKinsey chatbot joke wrote itself when I posted to X: 99.9% of the McKinsey chatbots output is "increase revenue, cut costs”.

Many replies noted that the job of “consulting” might be cooked now that AI can crank out PDFs and slide decks at the snap of a finger. After exchanging messages with a few consultants, I don’t think that will be the case (yet).

The output still relies on unique insights and firm partners will still come off the top rope to make sure the messaging is distilled and all the semi-colons look just right. And the actual document is only a fraction of the offering. Also, AI isn’t going to wholesale replace consultants because there are soooooooooo many organizations that are paying these very consultancies to cook up AI strategies and deployment.

As this excerpt from The Economist in 2023 shows, never underestimate how painstakingly slow tech adoption takes on the organizational level:

In the past two decades all sorts of mind-blowing innovations have come to market. Even so, according to the latest official estimates, in 2020 just 1.6% of American firms employed machine learning. In America’s manufacturing sector just 6.7% of companies use 3d printing. Only 25% of business workflows are on the cloud, a number that has not budged in half a decade.

Horror stories abound. In 2017 a third of Japanese regional banks still used cobol, a programming language invented a decade before man landed on the moon. Last year Britain imported more than £20m-($24m-) worth of floppy disks, MiniDiscs and cassettes. A fifth of rich-world firms do not even have a website. Governments are often the worst offenders —insisting, for instance, on paper forms.

We estimate that bureaucracies across the world spend $6bn a year on paper and printing, about as much in real terms as in the mid-1990s.

Feel like these consultancies could pick up even more work in the near-term because each analyst can crank out more decks. Notably, Accenture (!!) says it had $1.4B in generative AI-related consulting bookings last quarter. [Insert a slight chuckle]. I’m sure the other consultancies are racking up similar dollars.

However, that opportunity will eventually run out. Will McKinsey and BCG still be hiring the same number of junior analysts 10 years out?

Well, let’s ask ChatGPT. I inputted all of the above text and here was the output:

By 2035, McKinsey probably won’t grow headcount much. Instead, it’ll reallocate:

Fewer junior analysts hired

More AI product managers, tech consultants, and “prompt engineers”

Higher billables per head, less bloat

So: 30,000–40,000 employees by 2035 is a reasonable forecast — especially if Lilli continues maturing and clients don’t need 8 people to write “put the trash in bins.”

Cool, sounds like I’ll still have a lot of PDF slidedecks to mine for viral content.

This issue is brought to you by Liona AI

Launch a GPT Wrapper (Including ChatBots) in Minutes

As many of you SatPost readers may know, I’ve been building a research app for the past few years (Bearly AI).

Over that span, I’ve eaten over 890 egg white breakfast burritos while my co-founder built a flexible backend to manage all of the major AI APIs. We turned that backend into a product called Liona AI.

This easy-to-use platform lets your users and teams connect directly to OpenAI, Anthropic, Grok, Gemini, Llama, Cursor and more while you maintain complete control over security, billing, and usage limits.

Apple Watch at 10

As some of you business-minded folks may know, consulting firm Gartner invented something called the “Gartner Hype Cycle”. It describes how the expectations for a product change from pre-launch to launch to after launch.

I made a riff of it called the Apple Hype Cycle, which describes the expectation of new Apple products (it was pretty accurate until the recent Vision Pro and Apple Intelligence snafus).

My inspiration for this chart was actually the Watch. So many people hated on the product at launch but Apple has since sold over 280 million units, which is a stupidly high lifetime sales figure of $120B+. It's the best-selling watch in the world and has outsold the entire Swiss watch industry (Switzerland is bracing for when Apple makes a fondue).

Wired has a memory lane of the product including some nuggets:

Apple Watch was the baby of Apple's former design chief Jony Ive.

Ive wanted Watch to be like a piece jewelry and clashed with other team members on positioning (since Apple added fall detection and ECG to the Watch in 2018, Tim Cook has really pushed the Watch as a health, fitness and wellness device).

Cook originally wanted to call it "iWatch"...and thankfully lost that battle.

Apple Watch's success has been great for high-end Swiss watch brands by raising interest in the entire space.

"In 2022, nearly 80 percent of Apple iPhone owners also owned an Apple Watch, and it accounted for 56 percent of smartwatch sales in the North American market."

Speaking of The Verge, they also covered one of a my favourite details about the Watch a few years ago: Apple is the world’s apparently one of the world’s largest buyer of Swiss CNC machines.

These automated precision tool cost ~$2m each and make small metal parts. Rolex used to be the largest buyer of CNC machines. But that title now belongs to Apple, which owns 100s of them. Why? For the Apple Watch: the tool is used specifically to make slots for swappable wrist straps.

That’s it. How precise is the CNC (computer numerical control) machine? Per The Verge, an average CNC machine can cut pieces with a precision of +/- 50 microns (comparable to the LEGO fault tolerances; for reference, a strand of hair is ~70 microns). The Apple Watch is even more demanding: it requires a cut within +/- 5 microns (take that 2x4 LEGO bricks!). That’s a comically tight tolerance band. The multi-hundred million dollar investment has already paid for off: Watch straps are a $1B accessory business.

I bought a Watch during COVID but never got into it. The daily charging requirement was too much. I expend enough mental bandwidth remembering to floss every day — and even then, it’s more like 3-4x a week (which my dentist berates me about every quarter) — so the Watch was a bridge too far. I can appreciate the hype cycle but doesn’t mean I have to participate (other than the 3x AirPods I bought and lost the left bud for each somehow).

SIDE NOTE, Apple also took a massive L this week: a US judge accused the iPhone maker of lying in court and has forced it to allow app developers in America to sell their apps outside of the App Store without a fee (BIG Newsletter). The 30% Apple Tax looks toast (and CEO of Fortnite-maker Epic Games Tim Sweeney played the long-game perfectly by bringing the original lawsuit against Apple in 2020 according to M.G. Siegler).

Links and Memes

OpenAI released a new model (o4)…that was “An Absurd Sycophant” as detailed by Zvi Mowshowitz. This version overly complimented the user for the absolutely most benign statements. One user asked “why is the sky blue” and o4 replied “what an incredibly insightful question. You truly have a beautiful mind. I love you”.

Dafuq? Relax.

CEO Sam Altman admitted that the new model “glazes too much” (translation: gives excessive praise). While OpenAI may not have specifically turned the “glazing” knob up on purpose, Mowshowitz thinks it is at least the result of an A/B test that showed much higher engagement on the individual level (which was informed by those "thumbs up or down" feature after ChatGPT answers). The app quickly received thousands of 5-star reviews. But then OpenAI had to roll back the fawning personality after the most absurd glazing went viral. Longer term, the lab has reduced safety-testing time on its model releases and it shows. That's concerning for a product with 500m+ users.

Some people definitely want to get glazed (eg. the AI girlfriend and boyfriend apps). But too much glazing seems counterproductive and shouldn’t be the default for people that want: 1) good advice or analysis; 2) useful research; 3) people that literally don’t want an AI to glaze them because it is just kind of weird; or 4) people with mental health conditions that shouldn't be having all of their thoughts validated by a chatbot (although, it should be noted that certain chatbot therapists have been found useful for some users to work through personal issues).

Mark Zuckerberg was on the Dwarkesh Patel podcast talking about the next evolution of Meta AI. One line stood out, “As the personalization loop kicks in and the AI starts to get to know you better and better, that will just be really compelling.”

On that front, Meta launched its own app that has its own “Discover” feed, showing how your friends and family are using AI. It’s such a compelling opportunity, that OpenAI is also moving quickly down the road of “personalization” and is turbocharging the effort with the addition of ChatGPT memory features (OpenAI is also working on a similar Discover feed).

There are certainly benefits to having an AI know you well, but this glazing episode makes me a bit leery. If a model knows you well, it can subtly glaze you without the overt ick factor of what o4 just did. In that world, we’ll literally have millions of slightly different AI models all perfectly wrapped around an individuals quirks and interests. If engagement is the key metric, then these models probably won’t want to offend the user’s sensibilities and really tell them what they want to hear. We’ll all be living in perfectly curated (but often different) realities. If we were worried about social media addiction and filter bubbles, it’s about to go on steroids.

“My observation of algorithms in other contexts (e.g. YouTube, TikTok, Netflix) is that they tend to be myopic and greedy far beyond what maximizes shareholder value,” writes Mowshowitz. “It is not only that the companies will sell you out, it’s that they will sell you out for short term KPIs.”

PS. Zuck also went on the Theo Von podcast and apparently doesn't drink coffee because he likes to "rawdog reality" (honestly, that's insane...zero caffeine?).

***

Some other links for your weekend consumption:

The Savannah Bananas baseball is an incredible business story…Joe Pompliano details how the exhibition baseball team built a modern version of the Harlem Globetrotters that is taking all the best practices of live events, sports and entertainment to create what may soon be a $1 billion brand.

Ben Affleck’s press tour for his new film The Accountant 2 has been phenomenal…including him talking to Theo Von about his smoking cigarette memes and then telling Criterion Collection that the absolutely classic DVD commentary on Armageddon was “maybe my best work” (some of the funniest 2 minutes you’ll ever see).

ETF pioneer Vanguard is 50 years old…Nick Maggiulli has a retrospective on how founder Jack Bogle used a “minimally extractive” approach to create the passive investing giant and help to save investors $1 trillion in costs and fees (unfortunately, I didn’t take Vanguard’s advice in the 2020-2022 period and invested in some of the most braindead zero-revenue SPACs humanly possible).

"The group chats that changed America"...Ben Smith writes on a 300-person Signal group chat that influenced the politics of Silicon Valley.

North American hot dog vendors should seriously consider…serving their product in the style of Indian street food vendors.

“Watching [GPT] o3 guess a photo’s location is surreal, dystopian and wildly entertaining”…Simon Williamson with a breakdown on a very creepy AI use case and why it’s imperative to avoid real-time doxxing yourself (as an ironclad rule-of-thumb: a minimum of 48 hours have to pass before I post photos eating fast food drive-thru by myself in the parking lot AKA one of the most underrated places to have a peaceful lunch).

Spain has a national electricity blackout...and Works In Progress writes that it be due to how the grid was set up for renewable energy and a failed back-up electricity connection to France’s grid

The experience of being a dad on vacation…is perfectly encapsulated by this action scene starring Josh Brolin.

Margin Call and The Big Short are go-to films…for when the stock market is dumping and people want hilarious meme references. Both have been super relevant in the past month. Semafor has a great interview with Margin Call director JC Chandor (who wrote the film 82-page film script in 4 days).

“Researchers Secretly Ran a Massive, Unauthorized AI Persuasion Experiment on Reddit Users” and 404 Media found that these bots were often more persuasive than humans. One reason why was that they impersonated very personal human details. The subreddit was r/ChangeMyView and they were pissed, raising questions of research ethics. The whole incident just reinforces the view to mostly ignore online arguments, as perfectly illustrated by this classic Reddit post:

…and here them wild post including one of the most viral ones I’ve seen in recent memories. X user DreamChasnMike wrote that “i think 100 n***as could beat 1 gorilla everybody, just gotta be dedicated to the shit 🤣”.

The internet loves hypotheticals and tens of thousands of peopled chimed in with the post ultimately getting 285 million views. Never seen anything like it. The responses were bonkers including here, here, here, here, also here, here too, don’t forget here…and sure, here….ok, last one here (fine, final one here).

It culminate with MrBeast jokingly (??) teasing what would certainly be his most insane video ever. For the record, the single gorilla would obviously beat 100 men…although this wildlife biologist says gorillas aren’t smart enough to take on 100 men and would probably lose to 20-30 men (but the hypothetical I really want to know is if 100 Navy Seals could take on 10,000 Roman Centurion soldiers).

Did you see that Tyler Cowen asked o3 who would win the 1 gorilla vs. 100 and posted the link on Marginal Revolution? https://chatgpt.com/share/680f7069-bb28-8010-b55f-d080960f89d5

As a dad, I cringe looking at that picture. It looks like what I step on in bare feet at night trying to walk to the fridge.